Non-welded

Bow Spring Centralizers

Our

company provides various non-welded bow spring centralizers, which are designed

and manufactured as per API Spec 10D. The popular styles available are non-welded single bow spring

centralizer, and double-bow spring centralizer with high reliable quality,

which can be used to replace Weatherford centralizer.

We also can produce Welded Spring Bow Centralizer.If you need,please contact me.

Spring Centralizer Characters:

♦ Super-strengthen spring steel ,

♦ Model processing, no rivet , no welding

♦ 3-section structure for easy transport.

♦ Starting and resetting force conform to API standard.

♦ Easy for installation.

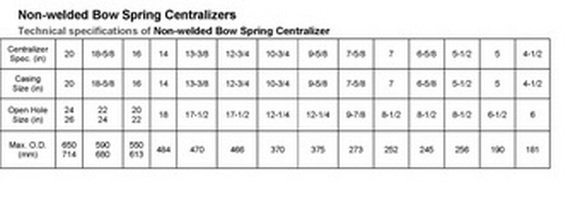

These can be shipped in half assembled condition for economy in shipping and storage costs. They are available in 4 1/2" to 20" sizes. Any special sizes or combination can available on request.

We also can produce Welded Spring Bow Centralizer.If you need,please contact me.

Spring Centralizer Characters:

♦ Super-strengthen spring steel ,

♦ Model processing, no rivet , no welding

♦ 3-section structure for easy transport.

♦ Starting and resetting force conform to API standard.

♦ Easy for installation.

These can be shipped in half assembled condition for economy in shipping and storage costs. They are available in 4 1/2" to 20" sizes. Any special sizes or combination can available on request.

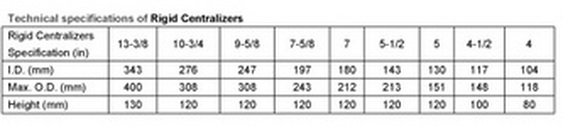

Cast Steel Rigid Casing Centralizers

As one useful cementing tool, rigid casing

centralizer enables casing run easily in wellbore with its shape of

stream-lined. There are two kinds of Rigid Centralizer available: spiral blade

rigid centralizer and straight blade centralizer.

The material for both kinds of centralizers can be cast steel or cast aluminum.

The material for both kinds of centralizers can be cast steel or cast aluminum.

Cast Aluminium Rigid Casing Centralizers

Our Spiral Solid Centralizers were developed in response to the need for better cementing in high deviated and horizontal well. They are design to provide optimum flow and its fins or blades overlap the entire 360-degree open hole circumference. Therefore it reduced flow area between the spiral provides and create vortex motion to increase fluid velocity with direction. Extra length of fins gives maximum centralization, high stand off and increase annular turbulence. Even without rotation, the relived angle fins/ blades induce turbulent flow for improved cutting and filter cake removal. As straight fins / blades provides only stand off while spiral solid Centralizer provide more effective Stand Off and Fluid swirl. The angle of the uniquely designed spiral fin produced maximum fluid swirl, thus maximum removal of debris from around the casing in any type of hole. Our Centalizer withstand high well bore temperature while providing maximum horizontal stand off. These Centralizers are Well head friendly and have high impact with shock resistance, along with optimum tensile and yield strength.

Our Spiral Solid Centralizer are constructed of one-piece high strength corrosion resistance Alloy Aluminum, Alloy Steel, Stainless Steel or Non sparkling Alloy Zinc. Centralizers are available in short length, long length and standard length. Further, they can supply fixed design and non-fixed design. These Centralizer are High graded castings followed with surface finishing on CNC Lathe, then rigid inspection make a quality product. All Centralizers are stove painted or coated with polyester powder. They are available in all sizes ranging from 3 ½” to 13 3/8” for any hole combination.

Our Spiral Solid Centralizer are constructed of one-piece high strength corrosion resistance Alloy Aluminum, Alloy Steel, Stainless Steel or Non sparkling Alloy Zinc. Centralizers are available in short length, long length and standard length. Further, they can supply fixed design and non-fixed design. These Centralizer are High graded castings followed with surface finishing on CNC Lathe, then rigid inspection make a quality product. All Centralizers are stove painted or coated with polyester powder. They are available in all sizes ranging from 3 ½” to 13 3/8” for any hole combination.

Roller Rigid Casing Centralizers

Tel :86-0532-87258955 E-mail:[email protected]

Fax:86-0532-82286211 MSN:[email protected]

Contact person:Mr.zhou,Miss.you

QQ:1265266705(Mr.zhou)294078033(Miss.you)

Address:Beiguan Of Jiaozhou City Shandong Provence

Fax:86-0532-82286211 MSN:[email protected]

Contact person:Mr.zhou,Miss.you

QQ:1265266705(Mr.zhou)294078033(Miss.you)

Address:Beiguan Of Jiaozhou City Shandong Provence